After our successful Monocoque development, we are now in a position to outline the Formtech Composites approach for further development, moving from the single piece Monocoque to Hybrid Body-in-White solutions: Continue reading >>

After our successful Monocoque development, we are now in a position to outline the Formtech Composites approach for further development, moving from the single piece Monocoque to Hybrid Body-in-White solutions: Continue reading >>

Exciting news – Formtech Composites and BBS Motorsport ready to present the latest protoype of their hybrid high-performance wheel to the market!

After years of engineering and testing the developing partners (BBS Motorsport and Formtech Composites) are going to present their latest prototype of an hybrid high-performance wheel. Continue reading >>

We are pleased to announce that the Visio.M was winner of the 2014 Electric Vehicle Competition in Germany!

Visio.M is the state-of-art Electric Vehicle in Europe with an Hybrid-Body-in -White.

Formtech Composites developed the Monocoque concept in conjunction wtih IAV, before going on to manufacture the solution. Continue reading >>

The Challenege: Build a show car for the Salon Prive at London’s exclusive Hurlingham Club in under 5 weeks!

From the first meeting in the middle of June (2009), Veritas and Formtech Composites took on the challlenge to work together to build the Veritas RSIII in less than 5 weeks from start to finish. Continue reading >>

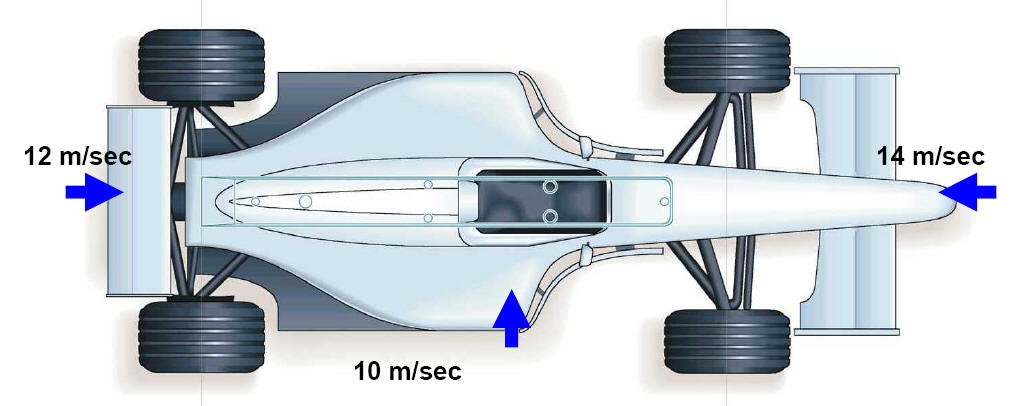

The following case study was written for an article in a motorsports magazine and takes the reader through the typical stages of designing a nosebox for a Formula One car.

The nosebox is the part of the car that connects the monocoque to the front wing. The nosebox has to take a number of loads: front wing loads of around 500 kg and the crash loads that it is subjected to in the FIA’s required homologation crash tests. Continue reading >>

Further to our news post on QinetiQ’s Zephyr HALE UAV, we are pleased to announce that the Zephyr flight records have been ratified by the FAI:

Formtech Composites’ capability to offer the complete solution from design brief to production has taken a step into the UAV sector of aerospace with manufacturing support on the QinetiQ Zephyr project.

This Unmanned Aerial Vehicle which operates within the HALE (High Altitude, Long Endurance) sector has successfully been launched at the US Army Yuma Proving Ground in Arizona. Continue reading >>

Formtech Composites worked with Cars International and Dash-CAE to modify the Super Aguri SA06 chassis from the 2006 season into their current guise as the FV10: reborn!

The FV10 ran this week in Southern Spain Virgin Racing’s Test/reserve drivers Luiz Razia and Andy Soucek racked up over 350 laps in temperatures of 38C. Continue reading >>

Formtech Composites was created in the ex-Super Aguri F1 Team (SAF1) and ex-Arrows Grand Prix International based at Leafield Technical Centre in Oxfordshire, UK. The Intellectual Property of both Arrows Grand Prix and Super Aguri Formula One teams were part of the purchase and for the basis on which Formtech has built it’s engineering knowledge base. Continue reading >>

Acoustic Emission is a passive testing technique that can detect the damage mechanisms of carbon fibre structures whilst under load. This technique will be shown in this paper to provide useful feed back to the designer to hone his design during the testing stage.